Manufacture process

The magic of enchanted beauty in artisan jewelry

We love jewelry and we are fascinated how a women can change, add the splendor of its beauty. Feel a pleasant touch of the precious metal delicately caressing your sensitive skin. See how silver finesse sensually embraces your body and stresses your natural beauty. Think of how much pleasure a small detail can bring, a detail designed and created especially for you to put you in a great mood and constant delight. Feel your body derive the utmost energy and power collected in the precious stones meticulously set in elegant forms and designs. Imagine passing-by men throwing their glances on your tasteful pendant decorating your neck. Notice the envious look of other women admiring your beautiful bracelet subtly embracing your wrist.

In every woman's life there are moments when you want to look beautiful and brilliant and nothing more that does not help than adequately sized jewelry. Jewelry manufacturers produce the ornaments, which will certainly help many of women to show up their best during important occasion and celebration. Preparation of art jewelry is a big challenge, even for the best manufacturers of jewelry. The specificity of those products is primarily artistry which must be characterized. Jewelery manufacturing process includes most advanced technologies and dedicated research. Jewelry making is a very composite process undergoing a long and slow procedure making it tought from the initial point to the concluding point. Each product undregoes a series of procedures before we get the net product as a beautiful jewelry piece of art.

The natural components of jewelry (stones, silver and accessories) will undergo multiple processes.These jewelries are unique and involve a lot of time and skill. Expect for personalized jewelry which are handcrafted, most of the jewelries are excudet by casting machines.

Following is a brief description of all processes involve in the manufacturing chain.

Buying stones and silver

First of all we buy the right set of silver. We have only stering silver. Sterling silver is also called .925 silver or .925 sterling silver. The .925 comes from the fact that sterling silver is an alloy mixed with other metals. .925, or 92.5%, is the minimum proportion of pure silver that must be included in the blend. The alloy is created to harden natural silver to make it durable and less prone to tarnish. Sterling silver for our art projects, jewelry making and crafts comes in wire, tubing, and sheets. Before silver is deposit in the bank first silver must be mined.

Every one of our suppliers will tell you that we provide top quality products and services. Silver bars, or silver bullion, is an expensive investment that must be carefully considered before purchase. Bars come in different sizes and weights and it's important that you know the weight and purity of any bar before we purchase it. Mexico is currently the world's largest producer of silver and is therefore the best place to buy. However, We are buying silver only in United States of America.

When we are buying our stone from around the world, we always ensure we gain the best and widest range of materials available. Everything they offer us is the best in the industry... Isn't this what you want to hear? Literally everything is possible. Quality transcends throughout these companies whether it be their work samples, production facilities, showrooms or stone stock. These are stone companies investing in professional equipment and high quality materials. These are "stone" companies which we enjoy a long standing and committed working relationship with. We have decided to work with the best in the industry, and it gives satisfaction not only to us, but to our clients as well.

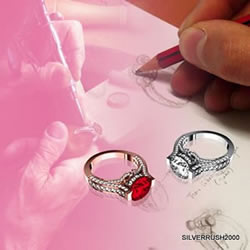

Designing a jewelry

Each piece of jewelry starts off with a concept. A concept is basically a rough design in the mind of the designer. The final design is the result of close cooperation between designer and craftsman giving the art object a real hand crafted origin. The designer's concept and drawings are used by the model maker to create the original piece of Jewelry.

Creating a jewelry design is a passionate yet difficult alchemy of embryonic ideas that knock against each other and are transformed. For the unfortunate designer the blank page is in front of him. Ah leave it alone don't darken the page mechanically; even pretend it can't be seen. Close your eyes and gently send messages to the brain imploring Mother Nature for help. Fleeting images appear shells, exotic leaves, wood texture etc.

Molding

Once the master piece of jewelry is complete, it is used to make a high technology mold, which in turn is used to make wax reproductions of the Jewelry.

After the sketch is complete with all the fine details, it is passed on to the molding section. In the molding department the very experienced professional molders then turn the sketch into a master mold which sets the base for the total process there from. The master mold is a very complex level of crafting as the final outcome rests on the master mold.

Casting (Lost-Wax Casting)

A metallic piece of jewelry will either be a unique piece, for example a unique custom made engagement ring or the model to be used for a rubber mold. It may be produced by lost-wax casting. This traditional method was already used by the ancient Egyptians.

The shape of the piece to be produced is initially shaped in wax or made of metal at a scale of 1.05 (or an average of 3%) to take into account solidification shrinkage (slight reduction of the dimension of the metal piece produced compared with the wax model. This is linked to the physical phenomenon of metals that are less dense as a liquid than as a solid, which results in a volume decrease as the metal cools and solidifies.

Settings stones

Setting consists in attaching a precious stone or gem to a metal mount by moving part of the metal. The techniques commonly used for settings include:

- Prong/claw Setting. The prongs are tiny pieces of metal from the mount that the setter folds over the stone's girdle securing the stone into place. This is the most common technique for solitary gems.

- Bezel setting. A tiny precious metal disk surrounds the stone. The sheet is folded over the entire perimeter of the stone securing it from the underside.

Polishing

Every part must be polished while the mount is being made. The entire mount is carefully made clean and polished to the highest degree of smoothness so that each and every part is attractively polished off. After stage setting, the polisher is credit worthy for giving the jewelry a concluding polish. All tinctures of the polishing compounds and 'rouge' must be meticulously got rid of either by careful washing by hand, or by use of supersonic cleaning baths.

- Mechanical polishing

Felt or cotton discs dipped in abrasive compounds are used to polish the surface of the metal. For difficult places to reach, (crevices, inside angles) cotton threads/strings in the same abrasive compounds are placed in the hard to reach areas and are vigorously rubbed. - Chemical polishing

This type of polishing is risky and is not appropriate for all alloys used in jewelry making.

Quality Checking

After the plating process is over, the product is brought to the checking department where each and every piece is checked with excessive attention and thoroughly checked for any defects. This process of quality checking is done by very experienced workers and all the defected pieces are sending back to the respective departments.

Talk to Our Jewelry Experts

Monday to Friday from 9AM to 5PM EST